100w Flexible Solar Panel Mounts

100w Flexible Solar Panel Mounts

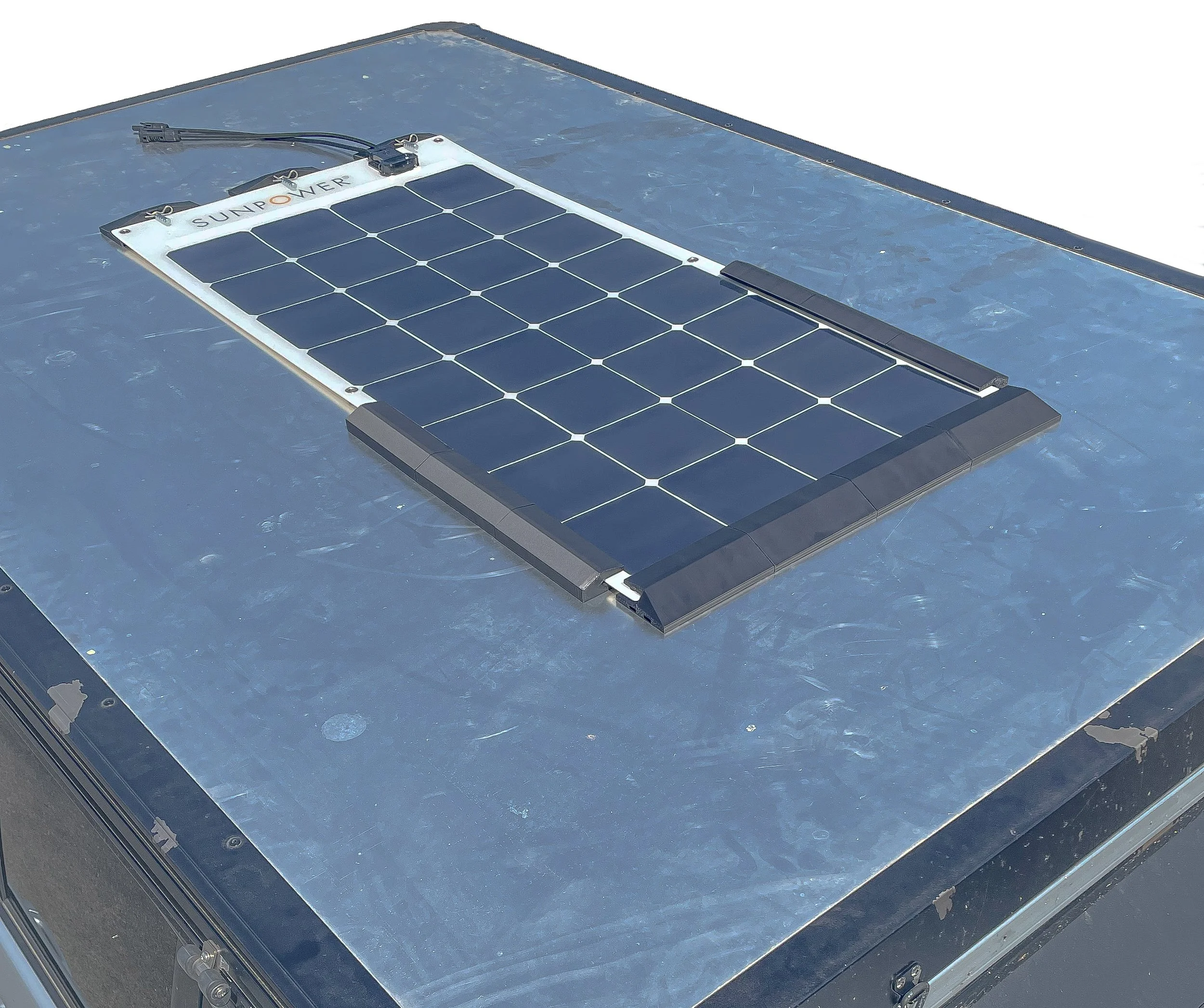

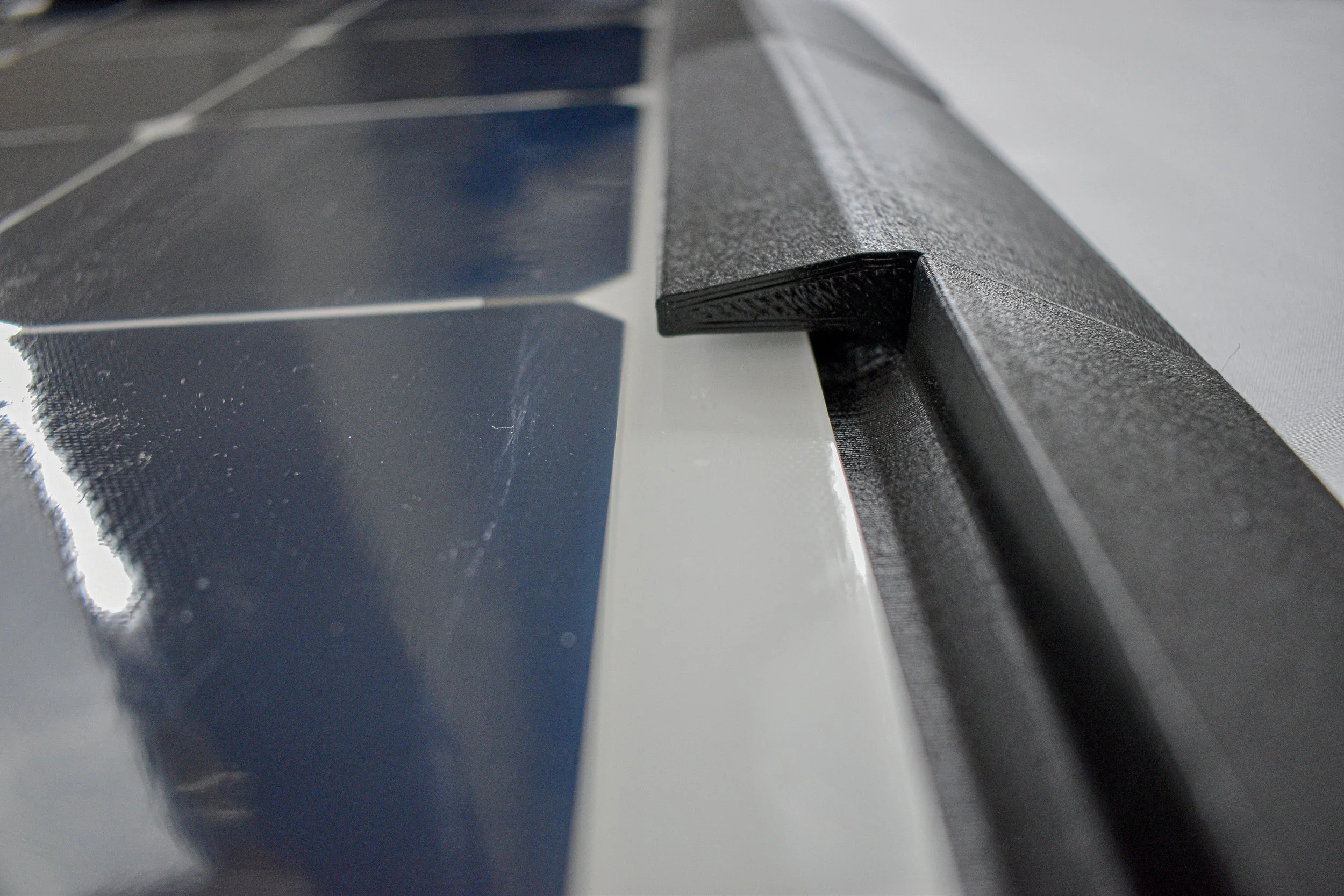

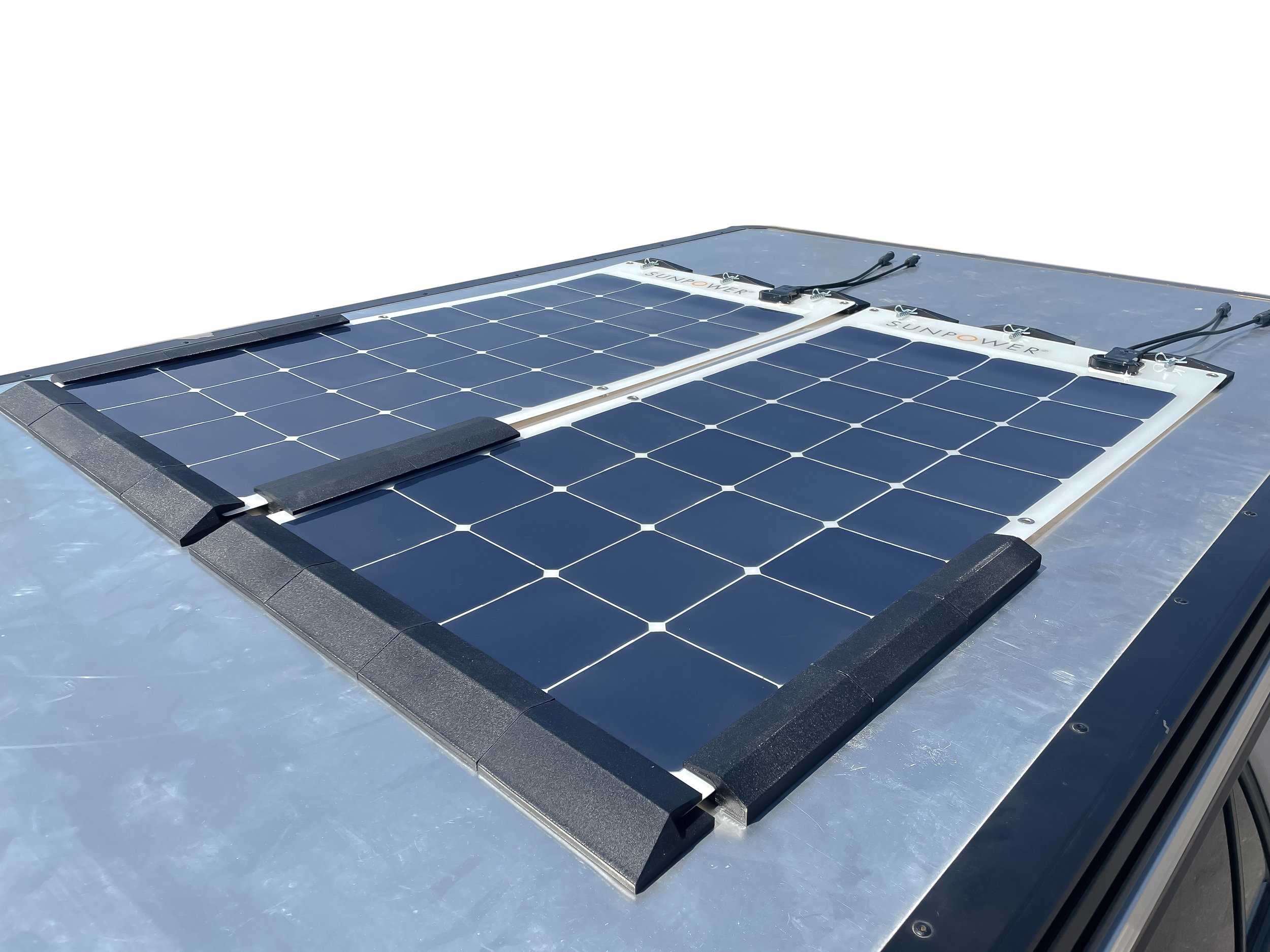

The Flexible Solar Panel Mount is a set of brackets that attaches your solar panel to the roof of your vehicle or camper. The Mount system is an aerodynamic, low profile track that allows your solar panel to be installed and removed in seconds.

This set of Mounts is designed to carry one 100w Sun Power Flexible Solar Panel on a flat mounting surface.

Mount Dimensions

Parallel: 50L x 24.5W x 1H inches

Perpendicular: 25L x 49.5W x1H inches

*If your vehicle/camper roof is not flat AND/OR you would like to use a different flexible solar panel, please email us at PhillipsSolarInd@gmail.com to have custom brackets designed for you.

Solar Panels are NOT included.

Mount System Benefits

The solar panels can be installed and removed from the Mounts within seconds

Does NOT void your solar panel warranty

No screws, bolts, drillings, or permanent adhesives are required

Designed to be low profile and aerodynamic to reduced noise and drag

Maximizes panel efficiency due to low thermal conductivity

Mount tracks can withstand the mounting surface flexing or bending

The Mount system allows flexible solar panels to slide in and out of the track so that you can collect solar energy while you’re driving as well as reposition the panels for better sun exposure while you are stationary. The Flexible Solar Panel Mount system also keeps the solar panels 7mm off of the vehicle roof while you drive, keeping them cooler to maximize their efficiency. The Mount pieces use a combination of heavy-duty magnets or double-sided tape and semi-permanent adhesives to eliminate the need to drill, bolt, or screw into the vehicle roof.

There are multiple Mount system designs and bonding options available depending on your needs. The Flexible Solar Panel Mounts can be attached to a steel mounting surface or materials such as fiberglass, carbon fiber, plastic, and aluminum. There are 2 general Mount classifications, single solar panel or double solar panel, and parallel or perpendicular panel orientation. There are also three different bonding methods, heavy-duty magnets for steel mounting surfaces and heavy-duty double-sided tape for non-magnetic materials. Both bonding methods use silicone adhesive to create a vacuum grip between the mounting surface and the Mount pieces, as well as protect the magnets or tape from the elements. The third option uses two sets of magnets on each piece to eliminate the need for silicone adhesives.

Options

Parallel vs. Perpendicular Orientation

The solar panel orientation is Parallel when it’s long side is parallel to the direction of travel (the side of the vehicle). When mounted Parallel, the solar panel will be removed and installed from the rear of the vehicle. Parallel Mounts are the recommended orientation for SUV’s and Jeeps.

The solar panel orientation is Perpendicular when it’s long side is perpendicular to the direction of travel (side of the vehicle). When mounted Perpendicular, the solar panel will be removed and installed from the passenger side of the vehicle. Perpendicular orientation Mounts are recommended for campers and campervans.

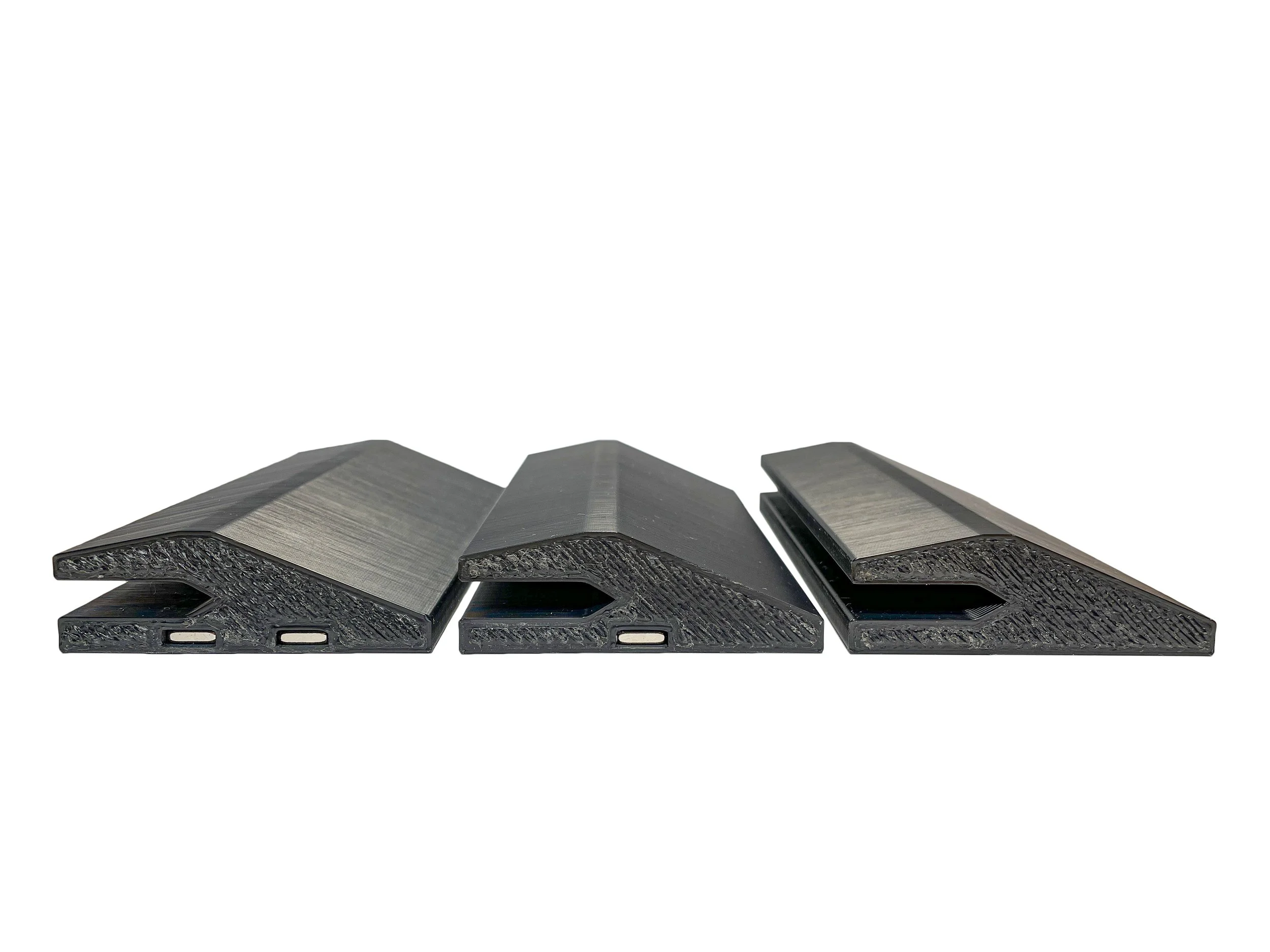

Double Magnet, Single Magnet,

No Magnet

No Magnet Mounts should be used for fiberglass, carbon fiber, plastic, or aluminum (nonmagnetic) mounting surfaces. These Mounts use a combination of heavy duty double sided tape and silicone to attach each Mount to the mounting surface.

Single Magnet Mounts are designed to be placed on a steel mounting surface for an extended period of time. Each Mount piece contains a set of two heavy duty magnets and is paired with silicone adhesive to anchor them to the mounting surface.

Double Magnet Mounts have two sets of heavy duty magnets built into each mount piece to eliminate the need for silicone adhesive. This Mount style is designed to be frequently removed and installed, it is NOT designed for highway speed applications.

Recycled-PETG, ASA, Carbon Fiber Polycarbonate

The Flexible Solar Panel Mounts can be printed out of multiple types of plastic based on your environment and budget.

Recycled Polyethylene Terephthalate Glycol (RPETG) is a great material for solar mounts in the Northern United States because it does not begin to soften until it reaches temperatures above 150 degrees Fahrenheit. Each Mount piece is coated in truck bed liner for additional durability. This affordable plastic is sourced from 100% recycled materials and 3D printed in Columbus Ohio.

Acrylonitrile Styrene Acrylate (ASA) should be used for vehicles that will be in hot environments such as the South West United States. The ASA Mounts are 3D printed at 490 degrees Fahrenheit and are rated for continual use at temperatures up to 180 degrees Fahrenheit. ASA plastic also has a high UV and chemical resistance for increased longevity. The filament is made in China, the Mounts are 3D printed in Ohio.

Carbon Fiber Polycarbonate (PC) is for those who require top of the line parts for their adventure or work vehicles. The polycarbonate filament is mixed with carbon fibers to increase its strength, flexibility, and heat resistance. Carbon Fiber PC filament is rated for applications up to 300 degrees Fahrenheit. It is one of the strongest 3D printing materials commercially available. The filament is made in China, the Mounts are 3D printed in Ohio.

Flexible Solar Panel Mounts printed out of recycled plastic.

IMPORTANT: ONCE THE FLEXIBLE SOLAR PANEL MOUNTS ARE PURCHASED, IT IS THE CUSTOMER’S RESPONSIBILITY TO

-Provide the correct rooftop measurements and dimensions before the mount pieces are manufactured and installed.

-Only use the solar panels the mount was designed for.

-Install the solar panel mounts on the vehicle and in the orientation it was designed for.

-Follow the install directions to completion.

-Perform monthly strength checks on the flexible solar panel mounts.

-Remove and replace any silicone sealant that has degraded.